1、用途特點 Product Feature

1.1 本機用于棉紡廠回收下腳棉中的有用纖維。

This machine is used for collecting useful fibers from cotton wastes.

1.2 適用范圍:清鋼落棉、低級棉的處理。

Application: Dropping cottons from Blowing-Carding units, and low grade cottons;

1.3 本機可與抓棉機、打包機及濾塵器等設備配套組成廢棉處理系統。

This machine can be used together with Cotton-plucker, Baler and Filter and other equipments to form the Waste-cotton Processing System.

1.4 廢棉開松除雜工藝合理先進,纖維損傷小。

With advanced process technology of loosening waste cotton and impurities removing, fibers can be much less damaged.

2、主要規格 Main Specifications

|

項目Item |

內容Contents |

備注 Note |

|

機 幅Work size(mm) |

1060 |

|

|

處理量Capacity(Kg/h) |

180~200 |

|

|

全機功率Overall power(Kw) |

20.15 |

包括凝棉器 Cotton condenser included |

|

打手直徑Beater Diameter(mm) |

400 |

|

|

外形尺寸 Outer size dimension 長H×寬W×高H(mm) |

5815×1636×3930 |

|

|

重量Weight(Kg) |

約About 6200 |

包括凝棉器cotton condenser included |

3. 機器結構 Structure

本機主要由凝棉器、角釘打手、小三角塵棒、棉箱、鼻形打手、分梳除雜箱(一)、鋸齒打手、分梳除雜箱(二)、塵籠吸粉塵短絨、排雜。This machine is composed by condenser, stud beater, small-angle dust club, cotton hopper, nose shape beater, carding-impurity removing box (1), sawtooth beater, carding-impurity removing box (2), dust cage, to remove short fibers dusts and impurities.

3.1 凝棉器由塵籠、風機、剝棉打手、箱體等構成,采用雙進雙吸風形式;塵籠兩端用毛氈徑向密封,簡單可靠,耐磨損。各部位傳動均由三角帶轉動。

Cotton-condenser is composed of dust cage, fan motor, stripper beater, body, with twin inlets. Both ends of dust cage are sealed by felt, simple and reliable, wear resistant. All transmission parts are driven by tri-angle belts.

3.2 打手棉箱 Beater box

棉箱位于凝棉器下方,內裝打手,下部位置裝有小三角塵棒排除雜質,及一對喂給羅拉。工作時棉箱儲棉量由光電開關控制。

Cotton box locates under the condenser, with beater inside, one pair of feeding roller and small angle-dust club is at the lower position to remove the impurities. The content level of cotton inside is controlled by Optoelectronic-switch.

3.2 分梳除雜器

Carding-impurity removing device

3.3.1 分梳除雜器(一)在棉箱下部,由輸棉簾、喂給羅拉、上下給棉羅拉、打手、塵格、排雜棍、塵籠、風機及剝棉羅拉等組成開松除雜。

Carding-impurity removing device (1) is at the lower part of cotton hopper, composed of cotton-feeding cloth, feeding roller, up and lower feeding rollers, beater, dust grid, dust cage, fan motor and strip roller, etc, to loosen the cotton and remove the impurities.

3.3.2 分梳除雜器(二)通過中間簾子、小墻板與分梳除雜器(一)相連,主要由喂給羅拉、給棉羅拉、給棉板、鋸齒打手、小漏底等組成第二道精細開松除雜。Carding-impurity removing device (2) connects with small wall and carding-impurity removing device (2) through cotton feeding cloth, composed by feeding roller, feeding plate, sawtooth beater, small under screen, is the second process of fine loosening and impurity removing.

4、工作原理 Work Principles

4.1 廢棉經管道輸送,纖維吸附至凝棉器塵籠表面,由剝棉打手刮下后落入棉箱。經給棉羅拉喂入打手對其以開松除雜,出棉落至平簾上,雜質經塵棒、排雜隨氣流送至纖維壓緊器收集處理。

Waste cotton conveyed through conduit, fibers attached to the cage surface of condenser, and scrapped out by strip-beater and dropped into the cotton hopper, and then is fed into beater through feeding roller, fibers would be loosened and impurities removed, fibers dropped onto the flat cloth; impurities would be blown into fiber-compressor to be collected.

4.2 輸棉簾子及喂給羅拉將纖維層喂入一對給棉羅拉供打手進行開松除雜,塵籠表面再次形成纖維層后由剝棉羅拉輸出至中間簾子。

Fibers are fed into one pair of feeding roller through cotton conveyance cloth and front-feeding roller, and then loosened by beater, impurities removed. Fiber layer formed on the dust-cage surface and then conveyed to middle conveyance cloth by strip-roller.

4.3 纖維層通過中間簾子和喂給羅拉進入給棉羅拉與給棉板形成的鉗口,供鋸齒輥進行第二次梳理開松除雜,最后通過塵籠凝聚,由剝棉羅拉剝取輸出。

Fiber layer enters feeding roller by middle conveyance cloth and front roller, and combed the second time by licker-in roller, and then condensed by dust cage, stripped by strip roller.

4.4 纖維層通過塵格和小漏底時,雜物經落雜區由排雜輥經風道排出機外收集。Fiber layer passes through dust grid and small cage screen, impurities drop and then extracted to outer side by impurity-roller and collected.

5、工藝要求 Process Requirement:

5.1 機外輸棉管道直徑300毫米;打手落雜排風管道直徑250毫米,接至配套纖維壓緊器,分開收集。Diameter of outer side cotton feeding pipes is 300mm, air-exhausting pipes for impurities is 250mm in diameter, connect to fiber condenser, and dusts would be collected separately.

5.2 鋸齒打手落雜排風管道直徑250毫米,接至壓緊器或直接進入濾塵器。廢棉喂入前必需安裝T式除鐵雜器裝置,避免金屬雜質進入設備造成損壞零部件或引起火災等事故。Impurity piper of saw tooth beater is 250mm in diameter, is connected to compressor or enters condenser directly. T type iron-removing device must be installed before waste-cotton enters, to avoid iron waste to enter equipment and damage the components and cause conflagration.

5.3 人工給棉時,應勤喂、少喂并手撿雜物,切忌將大團棉塊直接喂入。During manual feeding, should be higher frequency, less volume, and handle pick up the impurities, don’t feed in big mass of cotton directly.

5.4 配套濾塵器 Dust Filter

為確保廢棉處理機環境及正常開車運轉,與本機配套使用的濾塵需符合流程的排列及工藝要求選型濾塵機組。

To make sure the waste cotton processing equipment is in good condition and function well, Filter system should meet the requirements of arrangement and process requirements.

6、檢查調整 Inspect and Adjustment

6.1 開車前首先檢查各處隔距是否調整好,用手撥動打手是否有異常的聲音,回轉是否靈活。

Before start, check every gauge, use hand to turn beater to hear if there is any abnormal noise, to feel if it’s nimble.

6.2 檢查各緊固件是否可靠;檢查電機、減速器轉向是否正常,減速箱中潤滑油是否加至油標中線;電器是否靈敏,安全可靠。

Check and make sure every fastener is reliable; check and make sure motor, decelerator to be normal, make sure lubrication oil inside the decelerator is up to the middle mark line of the oil level indicator; electrics should be sensitive, safe and reliable.

6.3 檢查各傳動鏈條及傳動帶是否張緊適中。

Check and make every transmission chain and belt is appropriately tightened.

7、運轉及操作注意事項 Operation Instructions

7.1 調試結束即可正常開車,順序如下:

After debug, if everything is OK, equipment can be started, sequence as below:

a 塵籠(一) Dust Cage (1)

b 打手(一) Beater (1)

c 給棉(一) Front Feeding Roller (1)

d 塵籠(二) Dust Cage (2)

e 打手(二) Beater (2)

f 給棉(二) Feeding Roller (2)

g 凝棉器塵籠 Dust Cage of Condenser

h 凝棉器風機 Fan Motor of Condenser

關機順序則反之。Stop sequence is on the contrary.

7.2 操作注意事項 Operation Instructions

7.2.1 打手(二 )(鋸齒打手)因慣性啟動力矩較大,可初次啟動3~5秒后關閉,然后再開,反復2~3次,直至正常運轉。

Beater (2)’s inertia is so heavy it needs higher start torque, it can be started for 3~5 seconds and then stop before being started again, repeat 2~3 times to normal speed.

7.2.2 如因簾子棉層過厚,給棉羅拉傳動鏈輪跳齒或配套濾塵器風量負壓不足引起堵車時,可即時按下機身上的“給棉停”按鈕,等排除故障后再按“給棉開”。

If the fiber layer on conveyance cloth is too thick, transmission chain wheel would jump the teeth, or, when the negative air pressure is not enough the filter will be blocked, then the “Feeding stop”button can be pushed, then “feeding start” can be pushed to start after eliminating the block.

7.2.3 適時調節打手棉箱上的光電開關高度或給面羅拉速度調整,保持前后聯接穩定產量。

Timely adjust the height of the optoelectronic switch in the beater hopper, or adjust the speed of feeding roller, make sure the feeding is table and continuous.

7.2.4 單機使用時,出棉處必須及時轉移已處理纖維,防止堆積過高后返卷入塵籠,造成不良后果。

When this machine is used in singles, feeding roller should move out the processed fiber timely, avoid the fiber to accumulate and being drawn into the dust cage.

7.2.5 設備運轉時,嚴禁打開刺輥罩蓋和塵籠罩蓋!

During operation, covers of Lick-in and dust cage are forbidden to open.

8、維護保養 Maintenance

8.1 定期為減速器、軸承及相關傳動件加油潤滑。新車運行3個月后減速箱應重新換油,以后每年換油一次。

Periodically add lubrication oil to decelerator, bearing and other transmission components. After running for 3 months, decelerator oil of new machine should be replaced, and then replace once per year.

8.2 每班結束,清除機身和過棉道掛積的廢纖維與積灰。

After each shift, clean the machine body and the aisle to eliminate hanging waste fibers and dusts.

8.3 每班結束打開鋸齒打手罩蓋一次,檢查打手鋸齒是否完好,鑲嵌在鋸齒上的不孕籽、籽殼可用鋼絲刷清除。

After each shift, open the cover of lick-in roller, check the teeth, and remove motes inset between the teeth, which can also be removed by steel brush.

8.4 定期張緊或更換傳動三角膠帶。

Periodically tighten or replace transmission tri-angle belts.

9、用戶自理件:Parts prepared by user

9.1 用戶自理件:機外管道,機外電纜,基礎。

Parts prepared by user: conduits and wires outside machine,foundation.

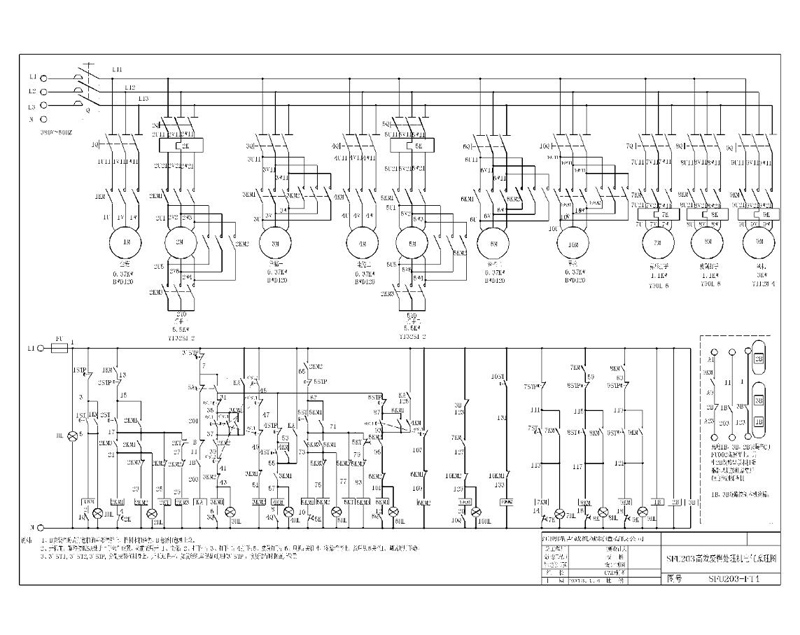

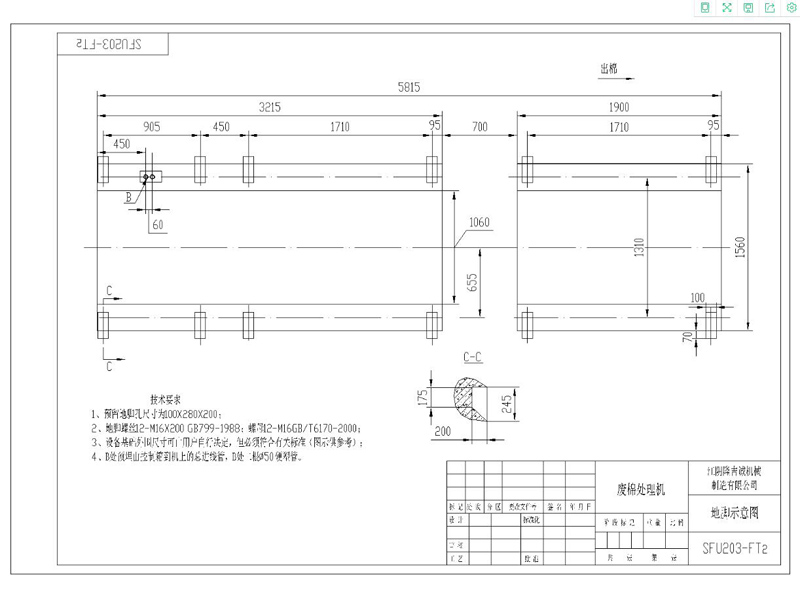

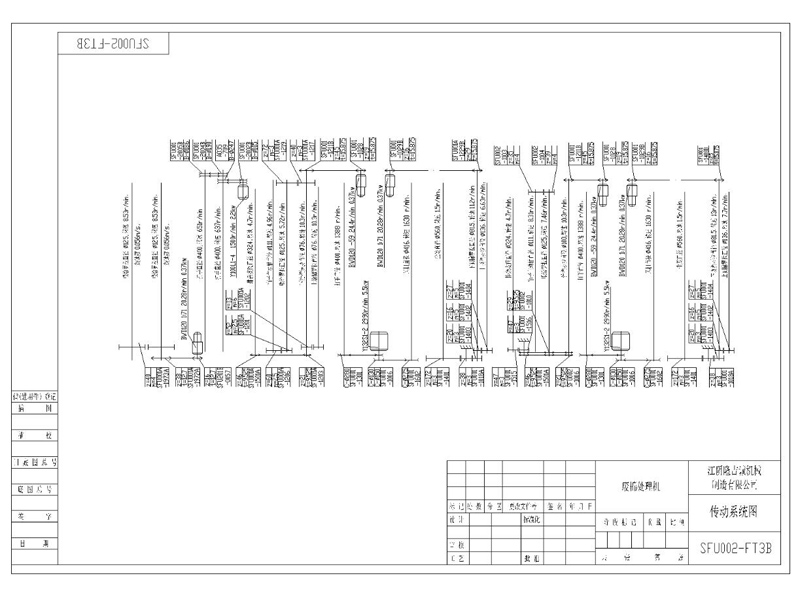

10、附圖 Appendix Figures

10.1 機器結構圖 Machine structure figure (FT1)

10.2 地腳示意圖 Foundation Instruction Figure (FT2)

10.3 傳動示意圖 Transmission Indication Figure (FT3)

10.4 電器原理圖 Electricity Principle Figure (FT4)